Whether you are a small-medium-sized furniture retailer or a multinational tech conglomerate such as Amazon, the bottom-line goal is high customer satisfaction. We all know the happier our customers are, the more sales we can make. Since customer satisfaction is so important to any business, when selling products, it's important to note stock levels during busy periods. When sales are high and stock is low, backorders can be your best friend… if you do it right.

Backordering is selling stock even if you don’t have it on hand. The product could still be in production or is currently on it's way to the warehouse. Instead of telling the customer that a product is out of stock resulting in a lost sale, offering a backorder is a great way to maintain customer loyalty. When we as consumers hear or see that a product is not available, it’s easy enough to hop online and find a similar product. But if given the option, many consumers would rather stick to the brand they know and love and just wait for the product.

It’s easy to confuse backorders with preordering as they both guarantee the product at a later date. Preordering is common for smartphones or even concert tickets where a set date is outlined when the initial news of the product is released. Backordering on the other hand sends the product to the customer as soon as it can be fulfilled without having to follow set release dates.

How to Manage Backorders

Maintain good relations with suppliers

Allowing backorders in your business is a good idea only if you can manage the fulfillment strategy. The first step is having a strong relationship with your supplier. Depending on your processes, you may order a product when your reach a sales quota or as individual sales come in. Either way, having a good communication plan set up between yourself and the supplier helps to avoid errors.

Know which products to backorder

When considering if your business is right for backorders think about long-term value. What kind of product are you selling and what is the common purchase cycle for it? Shoes are often impulse buys, a product that only last a few years. Furniture is well-thought-out and people are willing to wait for big-ticket items especially physically large items. Although, taking a guess isn’t always accurate.

Let’s look at an example as a furniture retailer. The right software, which we will get to later in this post, will help you determine stock levels. You may have a lot more stock of a 40-inch TV than you do of a particular couch because the TV is a high demand product with a high volume of orders while the couch is not so popular but still good to keep on the product line. The idea here is to purchase inventory quantities keeping in mind which items customers will be ok to backorder vs. what products customers will want on hand and which products will sell more quickly.

Communicate with customers

To be successful in your backorder strategy; communication is key, and it starts with the initial contact. If you have an eCommerce site, consider letting people know how long delivery will take. They don’t need to know whether the product is sitting in your warehouse or if it's on a ship coming across the Atlantic Ocean. All the consumer cares about is knowing when the product will be available and if that information is accurate. Once the sale is made it’s important to provide updates if there is a delay in the order to avoid damaging the brand's reputation. Think about how Amazon communicates their delivery times. On each product page we're able to see expected delivery date which can greatly help the purchaser on their decision to buy.

Leverage Reviews: Since online shopping is so common nowadays, consumers rely on customer reviews for authenticity. When a product is sold out, consumers actually view this as a good quality product and thus will want to purchase it. The harder something is to get, the more desirable it is. But be sure to have a good refund and return policy so customers know that if they change their mind, it can be hassle-free.

Train employees on the process

When introducing backorders as part of your business, your customer care team will no doubt be under more pressure. If customers are waiting a while for products, they may call in for updates or even inquire about revising the order. If they do, your team needs to have access to all the right information. Below we discuss what kind of software can give your employees what they need.

What software can help you manage backorders?

Implementing the right software to help you handle backorders is vital to its success. ERP or Enterprise Resource Planning Software is an all-in-one inventory and order management solution that can help you determine how much to order from suppliers based on historical information. You don’t want to overstock or understock so knowing exactly how much to order can be tricky. An ERP system will be interconnected meaning the information in your software and the information showing on your website are the same which is great for providing your team with all information they need especially if they are customer facing.

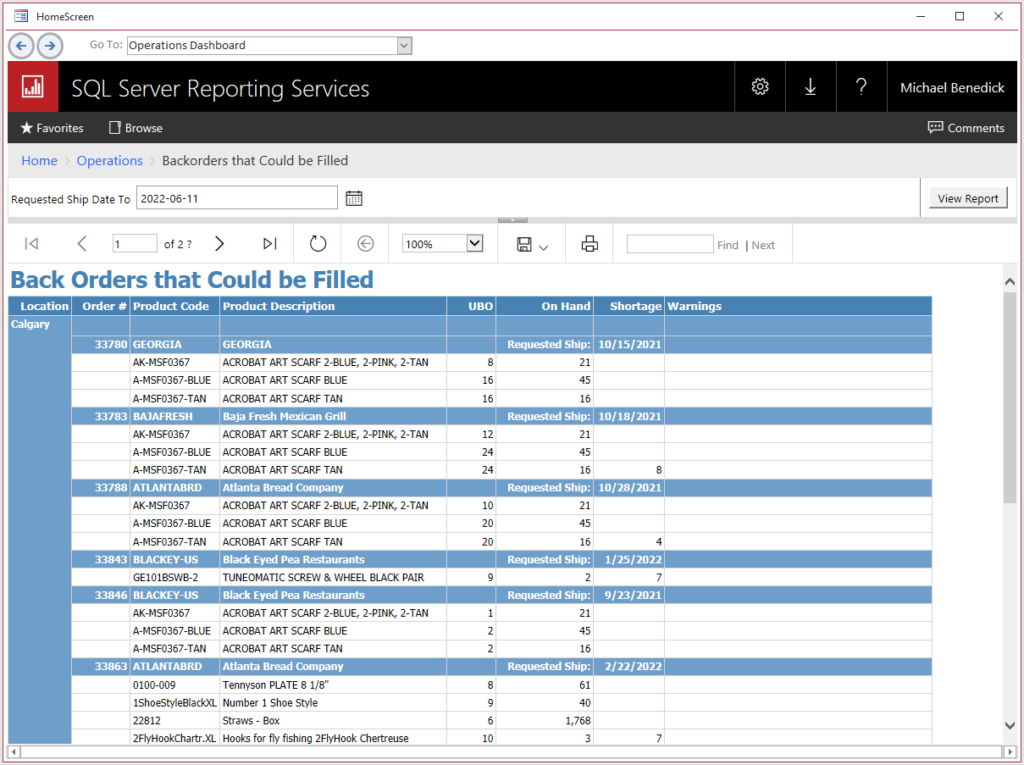

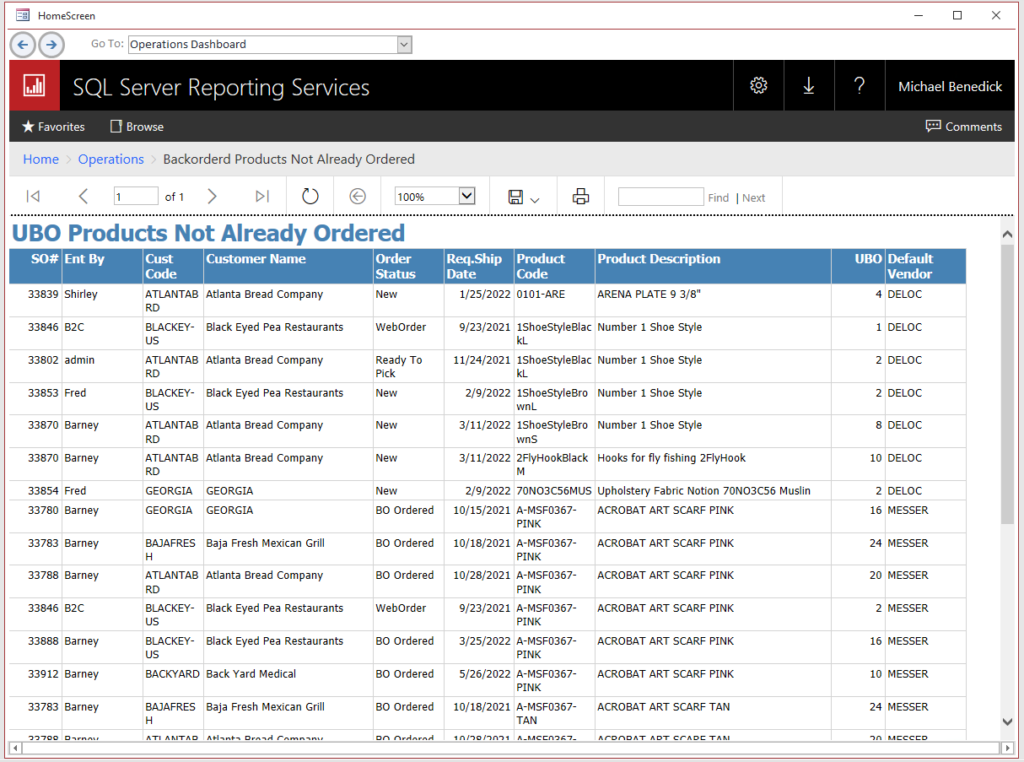

In order to combat these issues, Blue Link ERP includes SSRS (SQL Server Reporting Services) as part of the base application and can generate backorder reports for your team. Two reports are listed below: Back Orders that Could be Filled and UBO (Units on Backorder) Products Not Already Ordered. These two SQL Reports can help business owners manage their inventory by understanding how many backorders you have and how long it takes to fulfill them.

To further help manage the backorder process, Blue Link also includes the Automated Routines Manager (ARM) where you can automate an email to your buyer when there are enough units on backorder for a purchase order to be created. This automation ensures your team doesn’t miss out on opportunities and are on top of the backorders already placed.

If you’re interested in learning more about how Blue Link ERP can help you manage backorders, contact us today!

What if I hold no stock?

If you hold no inventory and rely on drop-shipping or a 3PL, backorders are even easier as you don’t need to handle any carrying costs which means faster shipping for your customers. Backordering can be risky but so is any new business process. Prepare, have a solid team of people and suppliers that support your business goals, and implement the necessary tools to make it happen effectively.